5 Ways ERP Will Redefine The Construction Industry In 2020

Construction Industry 2020

An ERP is an essential tool that significantly contributes to the knowledge that business leaders need, and the construction industry will be redefined in 2020 as projects become more complex.

ERP for construction integrates accounting, finance, human resources, operations, and sales functions for monitoring and reporting purposes.

1. Automating and Streamlining Business Processes

The comprehensive design of ERP construction software increases the efficiency of business processes and drives automation for construction management companies.

A centralized location for all corporate functions provides decision-makers access to a comprehensive view of delivery, design, development, finance, inventory, procurement, production, and sales.

Managers who have struggled to obtain a complete picture of different variables to complete their job on time and under budget. Many managers struggle from separate systems that do not talk to each other can rely on the integration of data that an ERP system provides.

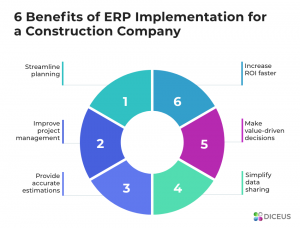

Image Source: https://diceus.com/erp-for-construction-company/

Workers and managers on the job site can check on the status of materials at any point, creating an independent approach to ensuring the development of high-quality work at each stage of the project.

With the enhanced communication capability that lets different teams share status information, engineers can observe the progress of a construction project at each stage through production.

Having accurate and up-to-date information can allow the team to inform the stakeholder departments about the need to purchase raw materials to maintain the flow.

Shared information in real-time improves a company’s productivity and ability to satisfy customer demands. Automated procedures in construction ERP prevent delays, reduce reliance on manual processes, minimize errors, and improve corporate profitability.

2. Quickly Respond To Project Changes

ERP software can help companies react promptly to changing conditions by detecting areas that need improvement. Some advantages of an ERP construction system include the ease of monitoring changes to determine their potential for effectiveness.

With modifications to existing processes, businesses can reduce costs and risks by streamlining processes that do not reflect a forward-thinking approach.

The combination of reduced operational and management costs, improved data integrity, and enhanced financial control can help companies meet the dynamic changes in the market.

ERP systems for construction companies provide managers with tools that can make reactions to challenging market behavior more productive. Real-time data analysis facilitates the planning, estimating, and adjusting processes that allow companies to respond to market requirements efficiently.

With access to system-generated reports regularly, decision-makers can react to market demands and respond aggressively to customer purchasing trends.

The comprehensiveness of the information that an ERP system provides can make forecasting more accurate and enhance opportunities to capitalize on changing market conditions.

3. Make Better Jobsite Decisions

A centralized database can improve collaboration, one of the most important reasons for construction ERP. Access to the opinions and knowledge of in-house expertise helps companies work from “a single source of truth” that reduces errors in decisions and helps control costs as well.

A centralized database makes construction projects more effective by providing relevant data to anyone in the company. The result of access to a complete knowledge base shows up in the reduction in the hesitation that often stalls projects.

Everyone who needs the information to do their job can find it in a single ERP system of compiled, stored, and shared data. Every construction organization needs integrated operations that involve the creation, fabrication, and delivery of products around the world regardless of the production location.

A contemporary ERP system keeps everyone in the production chain appraised of status through the ability to talk and interact “across a common digital playing field.”

A comprehensive construction ERP system enhances the decision-making process for all workers and decision-makers across construction projects. With the visibility that it provides, companies can make better and more informed business decisions faster. It is critical that companies leverage the appropirate resources to implement and maintain their ERP system, such as Oracle JD Edwards Consulting and JD Edwards Managed Services.

4. Reduce Operating Costs & Wasted Resources

The software for an ERP construction system can help businesses lower operational costs by replacing outmoded and time-consuming manual processes.

Productivity increases with streamlined procedures that reduce labor costs, improve precision, and minimize errors as cost-saving benefits. The ability to keep track of inventory life traffic cones, communication devices, and heavy equipment helps prevent the waste of resources by integrating it into the production planning process.

With control over job site inventory, an ERP system helps prevent the accumulation of excess product and subsequent costs of shipping, moving, and storage throughout a project’s lifespan.

The enhanced visibility of all divisions helps management achieve economies that produce significant savings. Cost management can result from the redistribution of managerial time.

Leaders can focus on areas that need improvement instead of trying to find snags in production that a streamlined ERP construction system handles seamlessly. Without the need to manually integrate and manage core production steps with paper-based scheduling processes that often produce errors, businesses can operate more efficiently.

5. Improve Customer Service

Enterprise resource planning experts note that managing customers in the digital age places unprecedented demand for businesses. Consumers trust online reviews as valued advisers, and companies face an almost continuous evaluation of services by millions of computer users.

Companies can achieve an adequate response by providing “client-centered goods and services,” and ERP for construction offers several different ways to do it. One of the most productive involves integrating a customer relationship management tool into the system to provide access to data “across all business functions.”

Another critical benefit provides accurate production planning that satisfies customers. Companies can exercise improved control over inventory while streamlining process schedules and coordinating distribution channels. Manufacturers can improve customer satisfaction with on-time delivery of products, a “critical performance metric.”

ERP construction software provides uniquely effective solutions that let businesses view data in real-time. With access to realistic data, decision-makers can check on up-to-date inventory status at any time of the day or night.

However, the quality of the enterprise resource planning software makes a critical difference in a successful implementation.

CONTACT US TODAY

FOR MORE INFORMATION ON GSI'S SOLUTIONS & SERVICES