5 Ways an ERP System Helps in Manufacturing

The Benefits of an ERP Sytstem in Manufacturing

Implementing ERP software in your business is an excellent way to handle growth opportunities and give your business a competitive edge. The manufacturing sector has the most applications for an ERP system.

Improve your supply chain management, give your customer service a lift, and increase your warehouse efficiencies.

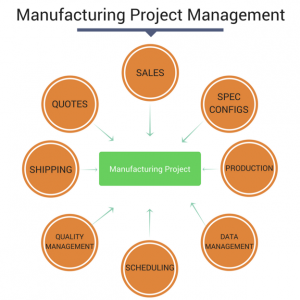

Enterprise Resource Planning, (ERP), helps businesses collect data into one central system that manages critical processes. With an ERP system, you get one solution to manage your financials, product planning, purchasing, scheduling, distribution, and customer relations.

An ERP can assist with critical processes governing your capacity utilization, projects, and procurements, as well as your equipment and assets.

Image Source: https://www.tcognition.com/blog/erp-software-manufacturing-industry/

ERP systems are vital for any business that wants to reach a self-sustainable and automated level where they have a handle on every aspect of the processes involved with a thriving business.

Gain Access to Operational and Financial Information

ERP systems offer your company smart solutions that are adaptable to your unique business functions. Complete integration with collection systems permits synchronization between accounting and collections. Most ERP solutions provide the following management functionality.

- Purchasing: Create requisitions, issue your purchase orders, and input your vendor invoices. Follow up on budgets, balances, and reserves while managing authorizations with electronic signatures and scan your documents directly into the system.

- Payments: Manage your supplier invoices and issue your payments through any payment method.

- Budgeting: Create budgets, as well as manage approvals and multiple budget versions.

- Loans: Monitor your outstanding loans, and receive data on loan load, future payments, and much more.

- Accounting: Manage your ledgers, record journal vouchers, and consolidate your ledgers into external financial systems such as credit card companies, salary systems, and banks. Generate reports every quarter or on-demand.

Create A Better Supply Chain

According to data from the Council of Supply Chain Management Professionals, US logistics costs for business accounts for more than $1-trillion per annum. This staggering figure is 7-percent of the United States GDP and more than the entire GDP of Mexico.

Image Source: https://erp-for-manufacturing.blogspot.com/

The US economy relies on well-managed supply chains. It's only through the implementation of ERP that businesses can identify, quantify, and maintain processes in their business that help them improve efficiencies. The following benefits of ERP will help your business grow into the future.

- Automatic purchasing: If your warehouse stock levels fall below critical levels, the system automatically orders new stock.

- Standardize processes: Save your company time and money by standardizing and automating your processes wherever possible. An ERP system allows you to provide your employees with a standardized system of tools designed to encourage teamwork, increase accuracy, and improve accountability while optimizing communications.

- Enhance transparency: Mistakes, waste, and fraud are supply chain problems facing every manufacturing business in the country. Use ERP to consolidate your software figures with a physical stock count. Every company experiences products that disappear or employees misplace. Enhancing your transparency helps to reduce unexplainable inventory and financial loss.

- Gain insights on your data: Receive accurate data in real-time to improve your decision making. This data gives you insight into the health of your supply chain in your manufacturing business. With ERP software, managers and users get instant access to production, purchasing, and inventory data to help them make critical decisions.

- Monitor your vendor performance: Monitor and rate your vendor metrics through the use of ERP systems. Review your vendor error rates and cycle times to assist you with running a smooth supply chain that gets outstanding vendor service.

- Improve your customer returns management: Your returns strategy is one of the foundational aspects of your supply chain. ERP systems help managers with handling returns effectively and efficiently, allowing for rapid remanufacture or reprocessing of all returns. Many companies focus on moving product, leaving their returns as a wasted product. Using ERP to assist with resolving a returns processing system will save the business money and time.

- JIT: Just In Time inventory management works seamlessly with ERP systems to increase turnaround and reduce inventory costs. These processes help to minimize overhead and mistakes with order fulfillment.

Get a Handle on Your Finances

Use ERP solutions to help you get an accurate snapshot of your business's financial position. Maintain all of your vendor payments and employee salaries with minimal effort.

Improve cost awareness – The uncontrollable variables and factors associated with supply chain management will leave managers unaware of the organization's expenses. An ERP system gives you centralized financial data points on how your company spends money. Streamline cost strategies and communication between departments.

Image Source: https://www.vrssoftwares.com/blog/how-do-you-need-erp-software-for-garment-manufacturing-industry/

Accounting – ERP integrates with many other business areas, such as management, human resources, and finance. Reduce your paperwork and avoid invoice mistakes and mix-ups.

Reduce your payment processing procedures and vendor waiting times by integrating your ERP system with Electronic Funds Transfers (EFT), and Electronic Data Interchange (EDI).

Improve Customer Satisfaction

Your business revolves around your customers. ERP systems help your management team and employees manage the sales and market dynamics of your company. Marketing, sales, and customer returns are three key areas where ERP provides your company with the data it needs to ensure you stay on top of your customer relationships.

Get a snapshot of customer interactions - ERP systems provide a holistic and comprehensive view of your customer processes, helping the support department monitor the customer journey. The system gathers data of every transaction, as well as customer support tickets and service outcomes.

Improve response times – Understand your customer issues through data. This strategy allows you to present the best customer solutions during support calls. ERP also lets you track the performance of your customer support.

Streamline processes – Operational intelligence software offered with ERP systems allows you to collect real-time data, as well as advanced analytics and AI are making ERP systems valid decision-making tools for your business.

Scale Your Global Workforce

ERP systems allow manufacturing businesses to coordinate multinational operations. While ERP is effective in managing capital and inventory, it's also useful for managing human resources as well. With an ERP system, you get better accountability from your employees by keeping processes on hand and available to all employees.

Regular training helps employees understand their role in the business. This strategy provides them with the training they need to improve operational efficiencies while maintaining accountability.

Relevant training combined with practical on-site process management is useful in bring the best out of your employees, wherever they are in the world.

Implementing and maintaining an ERP can be a big undertaking for a manufacturing company, and you will benefit from our JD Edwards Implementation Services and JD Edwards Managed Services to integrate your entire system together to work harder for you!

CONTACT US TODAY

FOR MORE INFORMATION ON GSI'S JD EDWARDS SERVICES